WhatsApp)

WhatsApp)

39 Item Part No. Image 1 DE1007 2 DE6000 3 DE6004 4 DE6015 5 DE6006 DE5024 6 DE6007 7 DE0027 tagout)

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Get the most out of your crushing circuit. Whether you are looking to minimize downtime, increase capacity, lower your cost per ton, or meet specific sizereduction requirements – can support you. Discover our wide selection of crushing services and parts.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

coal crusher practices SAMEA Workshop. Coal crusher and coal, is the most widely used powder separating equipment in the dry method cement production line The dust collector implements winnowing to the . Best Practices For Dust Control In Coal Mining.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Coal Centre – Coal sampling and analysis standards 4 Abstract Each year, billions of tonnes of coal are traded in regional and international market for use in power generation, steel and cement making, and many other purposes. In commercial operations, the price of coal

WhatsAppعرض المزيد

WhatsAppعرض المزيد

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Coal Crusher Operating Procedure. Impact crusher amp cement crusher manufacturer stedman an impact crusher is a machine that uses striking as opposed to pressure to reduce energy industry reduce the size of materials such as coal and biomass brick of the complete process to maximize production and keep operating costs low you both time and money when selecting the proper size reduction method

WhatsAppعرض المزيد

WhatsAppعرض المزيد

its operation. 5. Standards . Standards can be taken to mean Australian Standards, International Standards, Guidelines, Legislation, Codes of Practice, even the mine''s own set of standards. HOW DO I USE THE RISK ASSESSMENT WORKBOOK? This workbook provides a stepbystep approach to identify hazards, assess risks and allows

WhatsAppعرض المزيد

WhatsAppعرض المزيد

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Example: 60" x 89" primary crusher mill feed conveyor system Operating schedule calculation for 3 x 8 hours per shift Days per year 365 Tonnes per year 32,850,000 Metric tonnes per day 90,000 TOTAL TIME AVAILABLE 8,760 Hours per year UNPLANNED DOWNTIME (Subract planned or known downtimes) Industrial 0

WhatsAppعرض المزيد

WhatsAppعرض المزيد

The coal grinding installation fulfils the requirements according to the ATEX directive. The requirements are based on the zone classification specified for the individual plants. Noninert operation When grinding lowexplosive to moder ately explosive coal types, the system may operate

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Crushers: In CHP crusher work on principle of combination of impact and attrition crushing. In this type of crushing first coal is break due to impact and further scrub between two hard surfaces to get desired coal size. Some crushers are work only on principle of impact crushing. Generally these crushers are used before final crushers.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Standard Practice For Determination Of Gas Content Of Coal . 2 referenced documents purchase separately the documents listed below are referenced within the subject standard but are not provided as part of the standard astm standards d121 terminology of coal and coke d167 test method for apparent and true specific gravity and porosity of lump coke d1412 test method for equilibrium moisture of

WhatsAppعرض المزيد

WhatsAppعرض المزيد

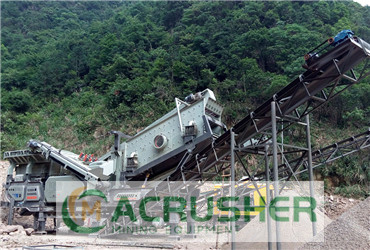

The company mainly manufactures mobile crushers, stationary crushers, sandmaking machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etc.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Coal. It is capable of crushing coal to 020mm, 2040mm, 40100mm. Concrete. This kind of mobile asphalt crusher is able to break concrete to 020mm, 2040mm, 40100mm.. Construction waste. A portable rock crusher could turn construction waste into reused building materials with diverse sizes of 020mm, 2040mm, 40100mm.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Crusher Works is an authorized dealer of world leading, quality equipment from many sources including , EDGE, BRETEC, DYNAPAC and BANDIT INDUSTRIES serving Alabama, Georgia, Mississippi, Tennessee and the Gulf Coast areas. We sell, rent and service products including mobile crushers, screens, shredders, picking stations, grinders, compactors, hammers, material classifiers

WhatsAppعرض المزيد

WhatsAppعرض المزيد

In general, coal crushers are categorized into two types and three types of primary crushers, as follows: Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

of standardsetting from the International Accounting Standards Board (IASB) has been intense in recent years with a constant flow of changes. One of the major challenges of any reporting framework is how best to implement it in the context of a specific company or industry. IFRS is a principles based framework and short on industry guidance.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Standard operation maintenance procedure of coal crusher. coal crusher standard operating procedure new zealand. We are the manufacturer of coal mining machine,roadheader,coal loader,tunnel mucking loader,backfilling machine,concerte pumping machine and so on. coal crusher standard operating procedure new zealand manufacturer, supplier.

WhatsAppعرض المزيد

WhatsAppعرض المزيد