WhatsApp)

WhatsApp)

Technical Data of SMH Series Standard Head Hydraulic Cone Crushers: Technical Date of SMH Series Short Head Hydraulic Cone Crushers: Details Introduction. Features of SMH Series Cone Crushers: crushing ability, high efficiency productivity, high capacity. system is reliable, provide safe and effective overload protection. of crushing cavity are for wide range .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone Crusher SSymons Tspring YHydraulic Bstandard Zmedium Dshort head Tsingle cylinder Dmulti cylinder Csupper heavy Cone diameter (mm/10) Feed length (mm/10) Type Size PYSB PYSB 0607 0609 0610 0910 0917 0918 Diameter of cone (mm) 600 (2'') 900 (3'') Feed opening (mm) 72 109 109 102 175 178 Discharge Setting 638 938 1338 922 1338 2538 Capacity (tons/hour) 1654 18 .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone crushers have been used as primary, secondary and tertiary crushers for quite a long time. They are widely employed for crushing hard and abrasive materials in both the aggregate and mining industries. Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

• Easytoread operating data Kubria® cone crusher (1,100 mm cone diameter) in a quartz porphyry works Feed grain size 5 – 32/44 mm Product size 0 – 22 mm Throughput approx. 150 t/h Kubria® cone crusher (2,100 mm cone diameter) for crushing granite Feed .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone Crusher Technical Characteristics. 15tph cone crushing plate machine technical data. Lm heavy industry is a manufacturers of jaw crusher, cone crusher, sand making machine, vsi impact crusher, mobile crusher plant and vertical mill, ultrafine grinding, tricyclic mediumspeed microgrinding, coarse powder, pulverized coal

WhatsAppعرض المزيد

WhatsAppعرض المزيد

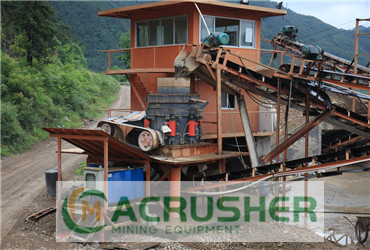

The mobile cone crushers MOBICONE are used in mediumhard to hard and abrasive natural rock, as well as for raw materials processing in mining applications. The cone crushers deliver excellent cubic final grains in the secondary and tertiary crushing stages. The MOBICONE plants are available in different sizes and versions and for different applications. The cone crusher is suitable mainly in the .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone crushers have been used as primary, secondary and tertiary crushers for quite a long time. They are widely employed for crushing hard and abrasive materials in both the aggregate and mining industries. Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Consult Corporation''s ® C150™ Jaw Crusher Brochure brochure on DirectIndustry. Page: 1/3

WhatsAppعرض المزيد

WhatsAppعرض المزيد

® MP 2500 Cone Crusher: The world''s largest cone crusher Features is responding to the customer challenge of reducing energy consumption and employing cost efficient technologies for minerals processing with the MP2500. The MP2500...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Technical Data of SDY Series Cone Crushers: Details Introduction. Features and technology advantages of SDY Series Cone Crushers: structure, advanced crushing principle and technical parameters, reliable operation and low running costs. large crushing force, high production efficiency and high yield. safety system is reliable and can provide safe and ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

HST cone crusher, short for single cylinder hydraulic cone crusher is the latest cone crushing equipment. The series cone crusher combines American technology, be the layer crushing an important breakthrough of principle and static pressure theory. Crusher cavity according to the crushing size requirement is divided into four cavity type hydraulic cone crusher, crushing, respectively, in fine ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

· This Market report covers technical data, manufacturing plants analysis, and raw material sources analysis of Spring Cone Crusher Industry as well as explains which product has the highest penetration, their profit margins, and RD status. The report makes future projections based on the analysis of the subdivision of the market which includes the global market size by product category, .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

® HP Series™ cone crushers feature a unique combination of crusher speed, throw, crushing forces and cavity design. This combination is renowned for providing higher capacity and superior endproduct quality in all secondary, tertiary and quaternary applications. Field proven for years, ® HP Series™ cone crushers are built to perform.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

cone crusher technical data Cone Crusher Technical Characteristics. 15tph cone crushing plate machine technical data. Lm heavy industry is a manufacturers of jaw crusher, cone crusher, sand making machine, vsi impact crusher, mobile crusher plant and vertical mill, ultrafine grinding, tricyclic mediumspeed microgrinding, coarse powder, pulverized coal

WhatsAppعرض المزيد

WhatsAppعرض المزيد

SMH series hydraulic cone crusher is a highperformance cone crusher. By optimized combination of the rotation rate, stroke and the crushing cavity, it realizes the laminated crushing and improves the yield greatly.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

CH890i CH895i Technical specification Product form: Stationary crushers and screens. CH890i and CH895i are technologically advanced, highcapacity cone crushers designed for crushing applications in mines or large sized quarries. Each crusher has a hydraulically supported main shaft which is supported at both ends. With a robust design, adjustable eccentric throw, a constant .

WhatsAppعرض المزيد

WhatsAppعرض المزيد

high capacity copper mining primary cone crusher technical. The mine is located in Para state, southeast of the Amazon region in Brazil. a gyratory primary crusher, secondary crushing utilizing two cone crushers, two 2 capacity from127,000 to 254,000 metric tons of copper in concentrates (Vale, 2008). . and the high volumes of flotation cells and columns required, the technical...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone Crusher technical data. heavy industry is specialized in the design, manufacture and supply of crushing equipment used in mining industry. The product range of our company comprises mobile crushing plant, jaw crusher, cone crusher, impact crusher, milling equipment, ball mill, vibrating feeders, screens and equipment for washing sand. Our product is widely used in mining ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

® HP300™ cone crusher is a mediumsized model in the renown ® HP Series™ cone crushers family. It is an efficient crusher utilized in aggregates production as well as in mining operations. Depending on the size of a crushing plant. ® HP300™ cone crusher can normally be found in the second, third or fourth stage of the crushing process.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone crushers crush the feed material in a circulating opening and closing crushing gap between bowl liner and crusher cone. Opening and closing also takes place simultaneously on the opposites sides of the crushing chamber. Cone crushers are available in different designs. With the cone crushers used by KLEEMANN, the crusher shaft is pressfitted into the main frame. The crusher cone carrier ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Technical Feature of Cone Crusher author:dua time: Cone crusher is a kind of advanced hydraulic crusher machine with high power, large crushing ratio and high production capacity, which is widely used for secondary and fine crushing of metal ore and construction stone, as well as the ultrafine crushing of hard rock, slag, refractories and so on.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cone crushers take care of secondary and tertiary crushing applications. Fine and mediumsized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall. The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machine ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Wearresistant steel plates for frame protection Excellent feed opening area Ushaped arm design, easy access for maintenance Technical specification Nominal power 315 kW (400 HP) Feed opening 225 mm (8 7/8") Weight 15 700 kg (34 600 lbs) Stroke range 18, 22, 25, 28, 32, 36, 40 mm (11/16, 7/8, 1, 1 7/64, 1 ¼, 1 13/32, 1 9/16") Cavities MF, M, C, EC, ECLS / ECTR EF, F, Cone crusher ...

WhatsAppعرض المزيد

WhatsAppعرض المزيد

The MOBICONE MCO 11 S is a mobile cone crusher with integrated tripledeck secondary screening unit. Thanks to the closed material loop, up to three defined final grain sizes can be discharged. It is mainly used in the second or third crushing stage, whereby the electric drive of the plant facilitates interlinking with other Kleemann crushing and screening plants. Thanks to its sturdy design, it is ideal .

WhatsAppعرض المزيد

WhatsAppعرض المزيد