WhatsApp)

WhatsApp)

This Business Plan describes the goals and some of the activities of the Artisanal and Small Scale Gold Mining (ASGM) partnership area of the United Nations Environmental Programme (UNEP) Global Mercury Partnership. It serves as a planning and communication vehicle both for Partners and others. The purpose of the business plan is to provide a framework for articulating common goals, and to

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Jiangxi mobile small scale gold processing Jiangxi mobile small scale gold processing plant +quality warranty,US 15,000 5 YRS Jiangxi Hengcheng Mining Equipment Co., Ltd. Trade Assurance. China (Mainland. Get Price

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Mobile Gold Washing Plant The mobile trommel washing plant is an optimized removable platform for gold recovery, applicable to small or medium scale of placer/soil gold ore processing which prefer to use mobile operation. Its advantage: less investment, less

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Each wash plant has three proportionately sized sluice boxes designed to optimize gold recovery in all conditions. Allinone Gold Mining Wash Plant Each machine is a complete portable plant; there is no need for additional screens or sluice boxes! At the top is an extreme duty grizzly bar section that will take up to 24inch rocks (91 cm).

WhatsAppعرض المزيد

WhatsAppعرض المزيد

unit is a versatile mobile placer processing plant that is virtually "plug and play". It is a self contained, portable unit that is well suited for small/medium scale commercial mining, exploration or batch sampling. Its mobility is specially suited to

WhatsAppعرض المزيد

WhatsAppعرض المزيد

This is a small scale gold ore processing plant that uses gravity concentration to separate the gold from the rock material It had a capacity of 12 ton per hour Leaching Gold Mineral Processing amp Extractive Metallurgy Jun 8 2016 Gold ore bodies can be accurately sampled by milling all of the ore from mine development work and

WhatsAppعرض المزيد

WhatsAppعرض المزيد

offers 889 5 tons small scale gold processing plant products. About 8% of these are Mineral Separator, 0% are Other Mining Machines, and 0% are Mine Mill. A wide variety of 5 tons small scale gold processing plant options are available to you,

WhatsAppعرض المزيد

WhatsAppعرض المزيد

This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners, and high gold recoveries. First, concentration

WhatsAppعرض المزيد

WhatsAppعرض المزيد

gold plant will be that of the leaching and carboninpulp circuit (CIP). The reagent and utilities operating costs associated with leaching, adsorption, elution and regeneration would typically make up some 15% of total operating cost, whilst the capital costs associated with these areas is about 16% of the total. Although not largest (capital and operating costs associated with comminution

WhatsAppعرض المزيد

WhatsAppعرض المزيد

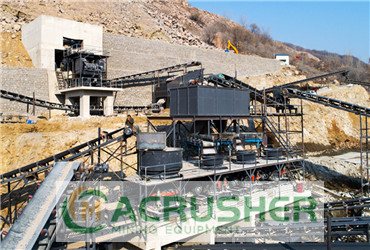

layout of small scale gold processing plant. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Small to medium scale mining equipment for the recovery of gold, chrome, tin, tantalite and more. We are based in South Africa, but our mineral processing plants are supplied globally.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Quality small scale processing plant on sale you can find small scale processing plant from the most reliable suppliers on

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Get mobile small scale gold processing plant Price. You can get the price of mobile small scale gold processing plant and a AC representative will contact you within one business day. Minerals processing and materials handling . AMTAS commenced operating as in Naval Base, Western Australia in 1982. At this time the Company was manufacturing Heavy Mineral Processing

WhatsAppعرض المزيد

WhatsAppعرض المزيد

unit is a versatile mobile placer processing plant that is virtually "plug and play". It is a self contained, portable unit that is well suited for small/medium scale commercial mining, exploration or batch sampling. Its mobility is specially suited to move up and down the alluvial plain, moving the plant to the ore instead of excavating and hauling ore to a stationary plant. The plant can

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Small Scale and Artisanal Miners No Mercury No Cyanide. iCON Concentrators are Used For: Hard Rock (No Chemicals Required) Alluvial / Placer Dredging; Upgrading Concentrates; Prospecting, Drilling Bulk Sampling; What is iCON? iCON is a family of Mineral Processing Products specifically designed to recover fine gold. iCON was designed by the professional Engineers at Falcon

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Small Scale Gold Ore Processing Plant Impact Pneumatics. This is a small scale gold ore processing plant that uses gravity concentration to separate the gold from the rock material It had a capacity of 12 ton per hour Leaching Gold Mineral Processing amp Extractive Metallurgy Jun 8 2016 Gold ore bodies can be accurately sampled by milling all of the ore from mine development work and

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Gold ore . Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

This was followed by its inclusion in the international television series ''Beyond 2000''.The product range at this time was aimed exclusively at the mining industry and also included gold mining, alluvial gold mining and processing equipment, gold jigs, scrubber trommels, alluvial sampling plants, alluvial gold plants, hoppers, feeders, conveyors and weighing systems.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Clean Mining will initially target small to midscale miners who can benefit from the costeffective leaching ore processing solution, which includes a plugandplay plant that can be customized

WhatsAppعرض المزيد

WhatsAppعرض المزيد

High Recovery Rock Gold Processing Plant Placer Gold Washing Gravity Concentrator Small Scale Gold Mining Equipment with Jaw Crusher/Wet Pan Mill/Shaking Table Hengchang mining machinery provide turnkey solution for mineral processing plant

WhatsAppعرض المزيد

WhatsAppعرض المزيد

911MPE has small gold mining equipment for sale and more specifically mineral processing equipment is best used in small scale extractive metallurgy operations operated by small miners or hobbyist prospectors and mining fanatics. 911MPE'' offers gold mining equipment as well as processing equipment applicable to most any base metals: copper, lead, zinc, nickel, tin, tungsten

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Alluvial gold processing plant / 90%+ Gold Recovery Ratio Hengcheng offers complete project solutions for Alluvial Gold Processing Plant. We are one of the leading project suppliers for Alluvial Gold Wash Plant Equipment and we work closely with our customers to fulfill their specific needs for customized package solution.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing

WhatsAppعرض المزيد

WhatsAppعرض المزيد

If YES, here is a detailed sample small scale gold mining business plan template feasibility report. Mining activities include the development of mine sites and the onsite processing of ore into a concentrate or bullion. Gold and silver ore mining companies typically retain ownership of the semiprocessed gold or silver products and pay for further refining on a tollcharge basis. If

WhatsAppعرض المزيد

WhatsAppعرض المزيد