WhatsApp)

WhatsApp)

A total of 210 large cement plants account for a cumulative installed capacity of over 410 MT, with 350 small plants accounting for the rest. Of these 210 large cement plants, 77 are in the states of Andhra Pradesh, Rajasthan and Tamil Nadu. Sale of cement in India stood at Rs 58,407 crore (US billion) in 9MFY20. Investments. According to the data released by Department for Promotion of

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cement Corporation of India limited CCI Plant . The pany has also put emphasis on water conversation and recycling of the waste produced in the cement production process Some of the well known CCI Cement Plants are Rajban cement plant: The Rajban Cement Plant is situated around 60 kilometers from the city of Dehradun in the district of Sirmaur The plant uses the dry process of manufacturing

WhatsAppعرض المزيد

WhatsAppعرض المزيد

As cement plant equipment and processes are monitored digitally, it enables you to react quicker, make smarter decisions on when to repair or maintain equipment based on unique data specific to your operation. This ultimately increases productivity by reducing downtime. FL develops customised solutions based on IoT technologies aimed at improving the performance of production equipment

WhatsAppعرض المزيد

WhatsAppعرض المزيد

· Cement manufacturing process components of a cement plant from quarry to kiln to cement mill.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

A cement plant consumes 3 to 6 GJ of fuel per tonne of clinker produced, depending on the raw materials and the process used. Most cement kilns today use coal and petroleum coke as primary fuels, and to a lesser extent natural gas and fuel oil. Selected waste and byproducts with recoverable calorific value can be used as fuels in a cement kiln

WhatsAppعرض المزيد

WhatsAppعرض المزيد

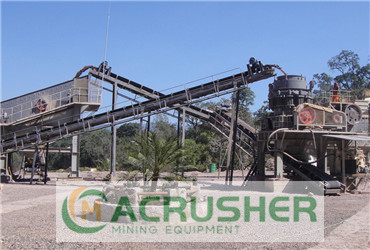

Cement plant process in hindi. The company mainly produces five series of products: crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and cement building materials equipment, which are widely used in metallurgy, mining, chemical industry, building materials, coal, refractory materials, ceramics and other industries.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

· 5. Plan for the implementation of the recommendations made for the cement plants in the CREP guidelines must be prepared. 6. Energy consumption per ton of clinker and cement grinding. 7. Provision of waste heat recovery boiler. 8. Arrangement for coprocessing of hazardous waste in cement plant. 9. Trace metals in waste material especially slag.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

· Soundness test of cement in Hindi Duration: 6 Lafarge Exshaw Cement Plant 124,906 views. 5:51. SUGAR | How It''s Made Duration: 7:55. Discovery UK Recommended for you. 7:55. Types Of Cement

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cement manufacturing process in hindi. The company mainly produces five series of products: crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and cement building materials equipment, which are widely used in metallurgy, mining, chemical industry, building materials, coal, refractory materials, ceramics and other industries.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

India: Shiva Cement plans to invest around US200m towards a new integrated cement plant in Sundergarh district, Odisha. The clinker unit will also include a 1Mt/yr grinding unit, an 8MW waste heat recovery (WHR) unit, 4Mt/yr crushing plants at its dolomite and limestone quarries, a connecting 10km belt conveyor and a dedicated railway siding with a 12km track to the main network.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

· Now cement plant grind the raw mix with the help of heavy wheel type rollers and rotating table. Rotating table rotates continuously under the roller and brought the raw mix in contact with the roller. Roller crushes the material to a fine powder and finishes the job. Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III

WhatsAppعرض المزيد

WhatsAppعرض المزيد

India at present is house to 120 large cement plants and about 300 mini cement plants. Among the large cement plants, The Cement Corporation of India (CCI) owns 10 cement plants. In exception to

WhatsAppعرض المزيد

WhatsAppعرض المزيد

We are leading cement plant manufacturers from technology that we introduce has its own merits. The Mini Cement Plant has the production capacity of 50 tons per day. The plant functions with lower power and fuel consumption, which has made the production process highly economical.

WhatsAppعرض المزيد

WhatsAppعرض المزيد

cement manufacturing process in hindi Products List Cement Manufacturing Process YouTube Mar 15 2012 This video is about to khalari cement manufacturing process Cement manufacturing components of a cement plant Cement manufacturing process components of a cement plant from quarry to kiln to cement mill More details Get. Get Price

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Duraton Cement Plant. India''s most advanced cement, Duraton Cement, rolls out of our plant located in Rajgarh village, Rajpura Taluka, District Patiala in Punjab, which can produce million tons per annum. The stateoftheart manufacturing facility was established in technical collaboration with FL of Germany, world leaders in cement technology and the plant produces cement at par

WhatsAppعرض المزيد

WhatsAppعرض المزيد

This flagship project with its members has developed, More than 60 cement plants in India have reported continual usage of alternative fuels, with 24% of the total alternative fuels consumed as biomass. The share of blended cement in the total quantity of cement manufactured in India in 2010 was 68%. This increased to 73% of total cement production in 2017, largely due to the market

WhatsAppعرض المزيد

WhatsAppعرض المزيد

· दोस्तों आज की ये Vedio बहुत Important है सभी Civil Engineers के लिए, क्युकी दोस्तों,आज इस विडिओ

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Process Discretion: Wet process, Semidry process, Dry process and Finish process. The environmental im pact of the cement production and its variations between different cement plants

WhatsAppعرض المزيد

WhatsAppعرض المزيد

SO 2 is emitted from cement plants via two main processes: 1. Sulphite impurities in the limestone and other raw materials; 2. Elemental sulphur contained in fuels, particularly coal and some alternative fuels. SO 2 emissions have risen significantly since the onset of the Industrial Revolution. 2 In 2014, 73% of the emissions come from conventional coal power plants, with the remainder

WhatsAppعرض المزيد

WhatsAppعرض المزيد

The Cement Manufacturing Process. India is the secondlargest producer of cement in the world producing 502 million tonnes of cement per year. There are 210 large cement plants producing 410 million tonnes of cement every year and 350 mini cement plants producing 92 million tonnes of cement per year. Thus, the cement manufacturing industries share a major part in the Indian economy. There

WhatsAppعرض المزيد

WhatsAppعرض المزيد

India''s Dalmia Cement (Bharat) has announced plans to set up a new facility at Jamuna village in Satna district of Madhya Pradesh. The project is worth an estimated (US), and is expected to produce 3Mta of clinker and of cement. The plans also include the construction of a 15MW WHR plant alongside the main unit

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Cooler exhaust fans move ton of exhaust air per 1 ton of clinker production. This process is a part of air blown into the cooler by cooling fans that are not useful for fuel combustion. In addition to these key process fans, cement industry also has many nonprocess fans. These fans work all together with bag filters, for the dedusting of

WhatsAppعرض المزيد

WhatsAppعرض المزيد

Tags: Cement meaning in Hindi. Cement meaning in hindi. Cement in hindi language. What is meaning of Cement in Hindi dictionary? Cement ka matalab hindi me kya hai (Cement का हिन्दी में मतलब ). Cement in hindi. Hindi meaning of Cement, Cement ka matalab hindi me, Cement का मतलब (मीनिंग) हिन्दी में जाने। What is

WhatsAppعرض المزيد

WhatsAppعرض المزيد